Ukubumba kwangaphambili ukwenza kunye noyilo lweemveliso zasimahla

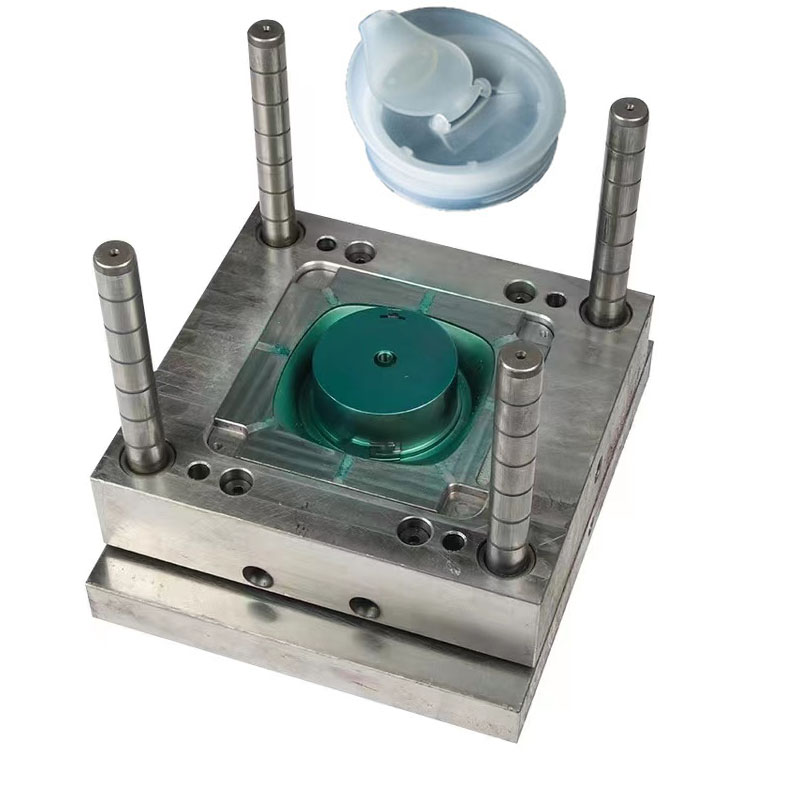

Ukubunjwa kwesitofu sePlastiki kwiZixhobo zaseKhaya

Ukubumba inaliti yePlastiki kutshintshe ukwenziwa kwezinto, kuvumela iinkampani ukuba zenze ngokulula umgangatho ophezulu, iinxalenye zeplastiki ezivelisa umthamo ophezulu.Nangona kunjalo, inkqubo yokuphuhlisa iinaliti zokungunda inokuthatha ixesha kwaye idle.Ukujongana nale mingeni, itekhnoloji yoshicilelo ye-3D iye yatshintsha umdlalo, inika izisombululo ezisebenzayo nezinexabiso eliphantsi.Kweli nqaku, siza kuphonononga izibonelelo kunye nokusetyenziswa koshicilelo lwe-3D lokubumba inaliti yeplastiki kwaye sixoxe ngeenkonzo ezibonelelwa yinkampani yethu.

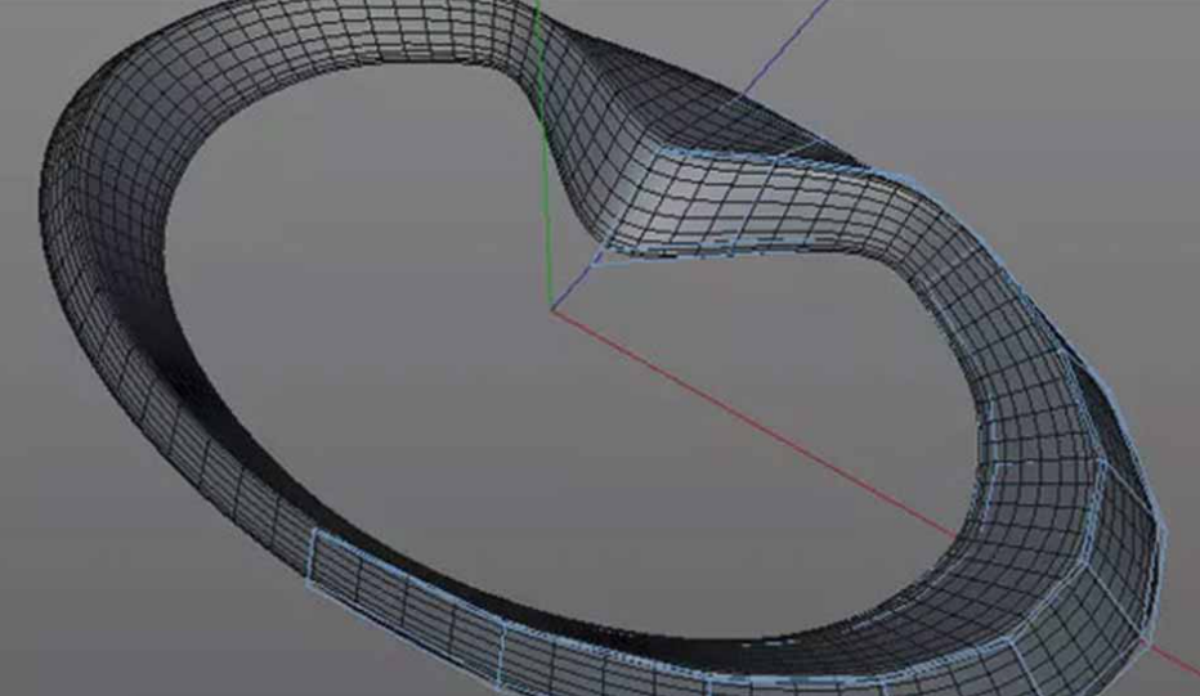

Inkampani yethu ngumvelisi we-OEM/ODM okhethekileyo kuyilo kunye nokwenziwa kwesitofu sokungunda.Siyakuqonda ukubaluleka kokuphucula iinkqubo zemveliso kunye nokuqinisekisa ukuchaneka okukhulu.Ukufezekisa oku, siqeshe abashicileli be-3D bakumgangatho ophezulu ukwenza iiprototypes eziphezulu.Aba matshini bokusika basizisele izibonelelo ezinkulu, beguqula indlela esiyila ngayo kunye nokwenza iinaliti zokubumba.

Inzuzo yokuqala yokusebenzisa iteknoloji yoshicilelo lwe-3D kukukwazi ukuvelisa uyilo lwesampulu enzima ngexabiso elifikelelekayo.Iindlela eziqhelekileyo zokwenziwa komngundo zidla ngokubandakanya iinkqubo zomatshini ezintsonkothileyo ezibiza imali eninzi nezitya ixesha.Ushicilelo lwe-3D lusivumela ukuba senze uyilo oluntsonkothileyo noluneenkcukacha kakhulu ngokuthe ngqo kwiimodeli zedijithali, ukuphelisa imfuno yomsebenzi obanzi womzimba.Oku kusivumela ukuba sinikeze izisombululo ezingabizi kakhulu ngaphandle kokubeka esichengeni ubunzima bezixhobo kunye nomgangatho.

Enye inzuzo ebalulekileyo yoshicilelo lwe-3D yokubumba inaliti yeplastiki kukulula koyilo olunokulungiswa xa kubhabho.Iindlela zemveli zokuvelisa ukungunda zihlala zifuna uhlengahlengiso oluthatha ixesha kunye nohlengahlengiso, okukhokelela ekulibazisekeni kwiishedyuli zemveliso.Nangona kunjalo, ushicilelo lwe-3D luvumela ukuba sibone kwaye sichonge iziphene zoyilo okanye uphuculo ngexesha lokwenyani.Ngokuphinda-phinda ngokukhawuleza ngohlaziyo loyilo oluninzi, sinokulinciphisa kakhulu ixesha elithathwayo ukugqiba uyilo lokubumba.Oku akukhawulezi nje ukukhawuleza inkqubo yokuvelisa, kodwa kwakhona kuqinisekisa ukuba isikhunta sokugqibela sidibana neenkcukacha ezifunekayo.

Ukongeza, itekhnoloji yoshicilelo ye-3D ivumela ukuba sizame izixhobo ezahlukeneyo kwaye sivavanye ukusebenza kobumba phambi kokuba siye kwimveliso yobuninzi.Oku kuguquguquka kusivumela ukuba senze izigqibo ezinolwazi malunga nokukhethwa kwezinto eziphathekayo, ukuqinisekisa ukuba i-mold yokugqibela yenza ngokusemandleni ngexesha lenkqubo yokubumba inaliti.Ngovavanyo olucokisekileyo lwemathiriyeli kunye neeprototypes eziprintiweyo ze-3D, sinokususa imiba enokubakho kwaye sinciphise iindleko zokuvelisa ngokubanzi.

Ukongeza, ushicilelo lwe-3D kwandisa ubungakanani kunye nokuguquguquka kwemveliso yokubumba.Iindlela zemveli zihlala zifuna ukwenza izixhobo zesiko kuyilo ngalunye olulodwa, okukhokelela kwiindleko ezongezelelweyo kunye namaxesha okukhokela.Ngoshicilelo lwe-3D, sinokwenza iimbumba ezinobungakanani obahlukeneyo kunye nobunzima sisebenzisa izixhobo ezifanayo.Olu buchule lusivumela ukuba sihlangabezane noluhlu olubanzi lweemfuno zabathengi kwaye lusinika inzuzo yokukhuphisana kwindawo yemarike.

Nangona itekhnoloji yoshicilelo ye-3D izisa izibonelelo ezininzi kwiinaliti zokubumba, kufuneka igxininiswe ukuba ayinakuthatha indawo yeendlela zemveli zokuvelisa ukungunda.Iinkqubo zoomatshini bemveli zisadlala indima ebalulekileyo kwimveliso yemizi-mveliso emikhulu.Nangona kunjalo, ngokubandakanya ukuprintwa kwe-3D kumsebenzi wethu, sinokuhlengahlengisa inkqubo yophuhliso lokubumba, ukunciphisa iindleko kunye nokuphucula ukusebenza kakuhle.

Isishwankathelo, inkampani yethu ibonelela ngokugqwesa kwimveliso yokutofa yokubumba isebenzisa itekhnoloji yoshicilelo ye-3D yangoku.Ngobuchule bethu kuyilo lokubumba kunye nokuveliswa, kudibaniswa neenzuzo ezibonelelwa ngoshicilelo lwe-3D, sinokubonelela ngokubumba okusemgangathweni ophezulu ngexabiso elifikelelekayo.Ukusetyenziswa kwetekhnoloji yoshicilelo ye-3D kusivumela ukuba senze uyilo lwesampulu entsonkothileyo, sihlaziye uyilo ngoko nangoko, sizame izixhobo ezahlukeneyo, kwaye sandise ubungakanani kunye nokuguquguquka.Ngokudibanisa izibonelelo zeendlela zemveli kunye nezanamhlanje, siqinisekisa ukuba abathengi bethu bafumana esona sisombululo silungileyo kwiimfuno zabo zokubumba inaliti yeplastiki.

Iinkcukacha zeMveliso

| Indawo yeMvelaphi | eTshayina |

| Igama lebrand | HSLD/ Yenzelwe wena |

| Indlela yokuBumba | Fans Plastic Isitofu Mold |

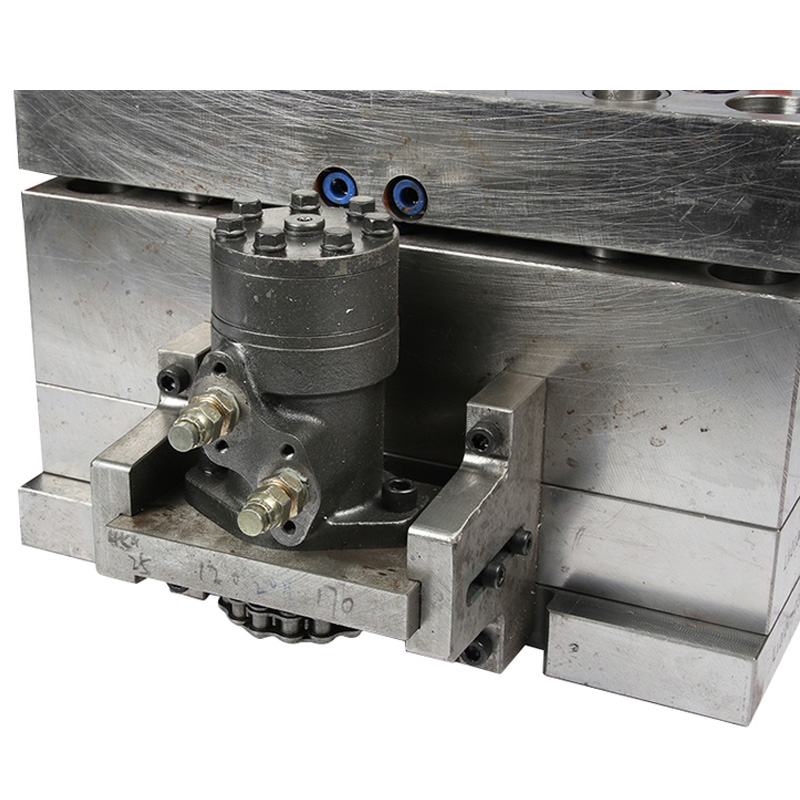

| Izixhobo | I-CNC, i-EDM yokusika umatshini, oomatshini bePlastiki, njl |

| IMveliso yeMveliso | Intsimbi: AP20/718/738/NAK80/S136 Iplastiki: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Ubomi boMngundo | 300000 ~ 500000 Shots |

| Imbaleki | Imbaleki eshushu okanye iMbaleki ebandayo |

| Uhlobo lwesango | Umda / indawo yePin / iNqanaba / iSango elisecaleni |

| Unyango lomphezulu | Imatte, ikhazimlisiwe, iMirror ipolishiwe, ukuthungwa, ukupeyinta, njl. |

| Umngxunya womngundo | Umngxuma omnye okanye ophindaphindayo |

| Ukunyamezelana | 0.01mm -0.02mm |

| Umatshini wokutofa | 80T-1200T |

| Ukunyamezelana | ± 0.01mm |

| Isampulu yasimahla | ekhoyo |

| Inzuzo | isisombululo esinye sokumisa / uyilo lwasimahla |

| Indawo yosetyenziso | Iimveliso ze-elektroniki, iimveliso zobuhle, iimveliso zonyango, iimveliso ezisetyenzisiweyo ekhaya, iimveliso ezizenzekelayo, njl |

Factory Iinkcukacha

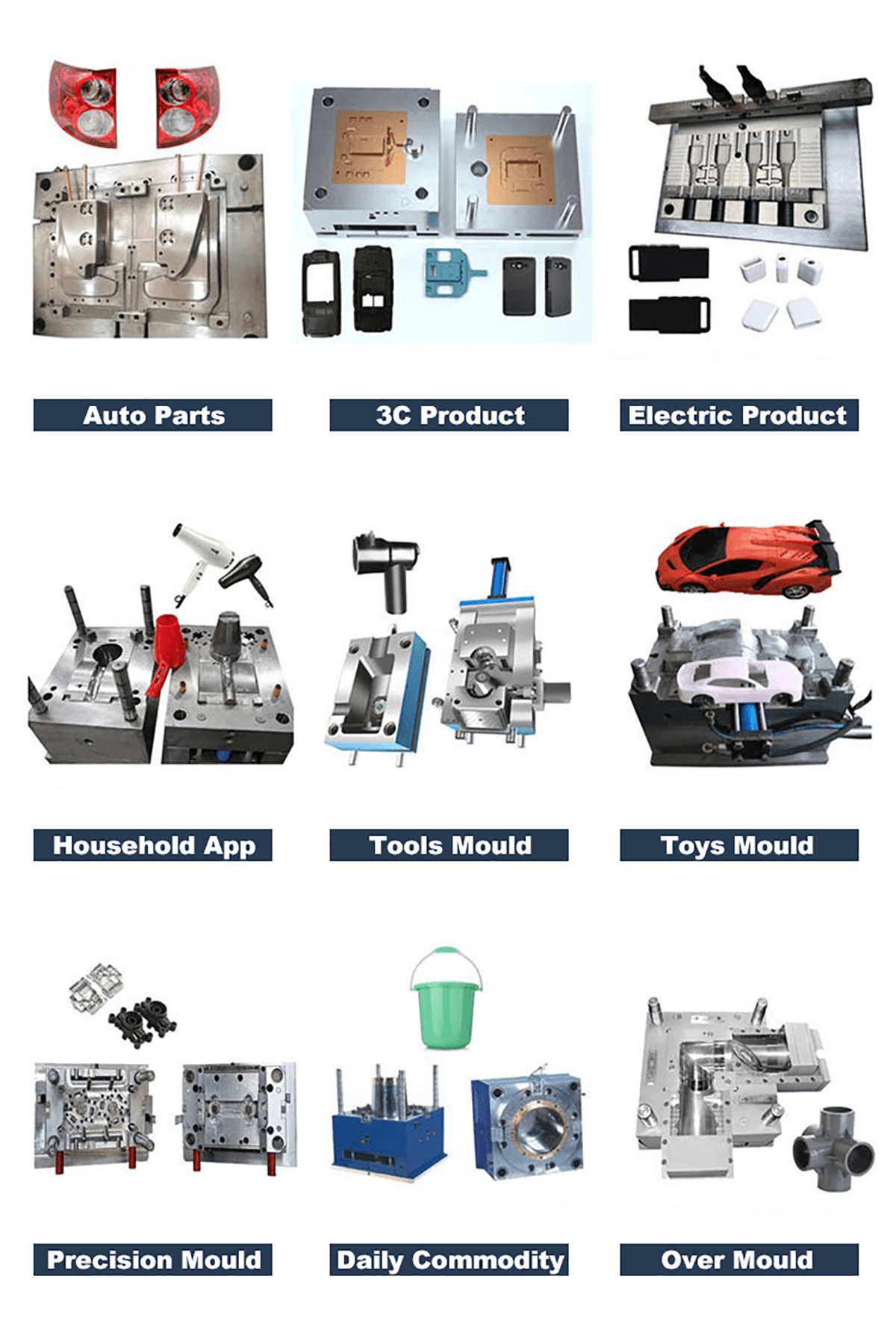

More Molds

Ukuthunyelwa ngenqanawa

Inkonzo yokupakisha ekhethekileyo kuwe: Ityala leplanga elinefilimu

1. Ukuqinisekisa ngcono ukhuseleko lwempahla yakho, professional.

2. Ilungile kwimeko-bume, iinkonzo zokupakisha ezifanelekileyo nezisebenzayo ziya kubonelelwa.

FAQ

I-HSLD: Ewe, ngokuqhelekileyo iindawo ezisecaleni ze-die casting mold sinokufaka i-mold, i-mold frame, i-window core, i-core ehambayo, intloko ye-nozzle.Ungajonga kwaye uxelele ukuba zeziphi iindawo ezisecaleni ozifunayo.

I-HSLD: Isifakelo sethu sokungunda senziwe ngeDAC.

I-HSLD: Isiseko sethu esishukumayo senziwe nge-FDAC.

HSLD: Ewe.

I-HSLD: Izixhobo ezahlukeneyo zinokuchaneka okwahlukileyo, ngokubanzi phakathi kwe-0.01-0.02mm