Ukubumba kwangaphambili ukwenza kunye noyilo lweemveliso zasimahla

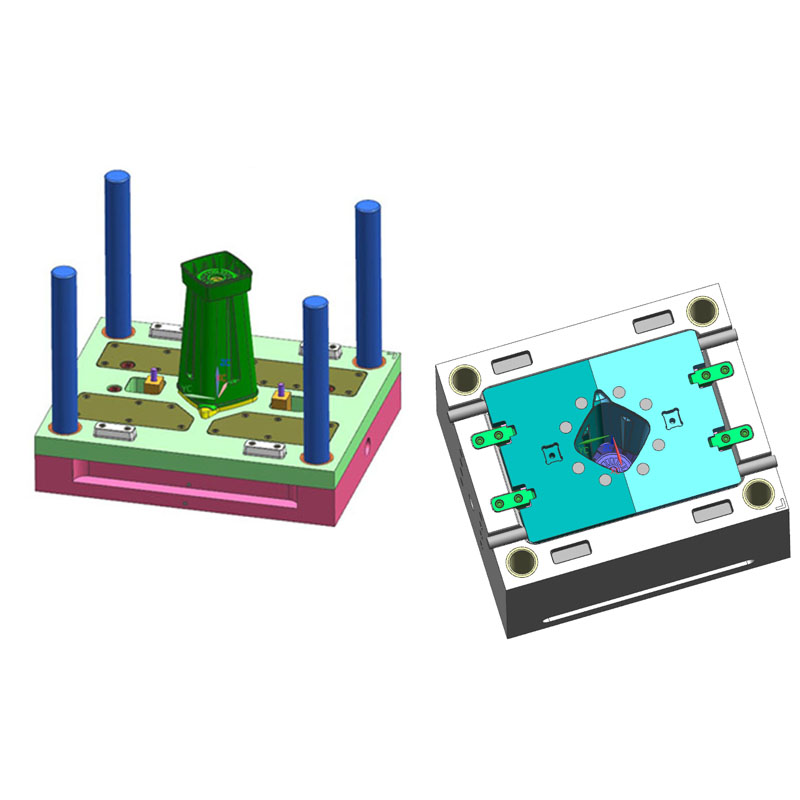

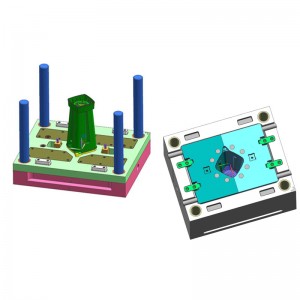

Ukubunjwa kwesitofu sePlastiki kwiZixhobo zaseKhaya

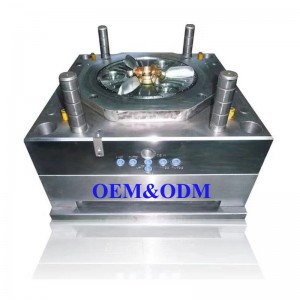

Izixhobo zasekhaya ziyinxalenye yekhaya ngalinye.Abathengi baxhomekeke kubo ekuphekeni, ukuzilungisa, ukonwabisa, kunye nezinye izinto ezininzi ezibalulekileyo.EHongshuo Mold, sisebenza ngokukhethekileyo ekuboneleleni ngezisombululo zokubumba inaliti kumashishini enza ezi mveliso zibalulekileyo.Sizinikezele ekunikezeni uyilo kunye neemveliso zeplastiki zezixhobo zasekhaya ezenziweyo kwaye zinikezela ngamava amnandi omthengi.

Iimolds zesitofu sesixhobo sasekhaya zibonelela ngesisombululo esixabisekileyo sokunciphisa inkunkuma yasekhaya ngokwenza iinxalenye zezixhobo ezahlukeneyo ezifana noomatshini bokuhlamba, iifriji, kunye nezinye izixhobo zasekhaya.Ezi zibumba zenziwe ngezinto ezomeleleyo ezifana nentsimbi engatyiwayo kwaye zinokulungiswa ukuze zilungele iimfuno ezithile zesixhobo ngasinye.

Njengomthengisi othembekileyo kubavelisi abadumileyo bezixhobo zasekhaya kunye nezixhobo zeofisi, iHongshuo Mold ibonelela ngezixhobo ezibanzi ukuze abathengi bethu bakwazi ukugxila kwizinto eziphambili kwiimarike zezixhobo zasekhaya: iziphene zero kunye neendleko eziphantsi.Ubuchwephesha bethu bunabela ekwakhiweni kwamacandelo ahlukeneyo emveliso yasekhaya, kubandakanywa nezo ziyilelwe ukusetyenziswa ekhaya, njengeendawo zokutofa koomatshini bokuhlamba kunye neemveliso zasekhitshini.Ukongeza, sinamandla okwakha izixhobo zeofisi ezifana nabashicileli kunye neekhompyuter, kunye nezikhongozeli zokutya ezinodonga olubhityileyo.

Ukubunjwa kwesitofu sePlastiki:

Inkqubo yeNguquko eyenza iintlobo ezahlukeneyo zeeMveliso zePlastiki eziluncedo

Kwimveliso, ukubumba inaliti yeplastiki ibe yinkqubo yoguquko etshintshe ngonaphakade indlela ezenziwe ngayo iimveliso zeplastiki.Ivula indlela yokuvelisa umthamo ophezulu, imveliso enexabiso eliphantsi kunye nokuphindaphinda okubalaseleyo kunye nokuchaneka.Eli nqaku lijonge ukuphonononga umhlaba wokubumba inaliti yeplastiki kunye nokukhanya kwiimveliso ezahlukeneyo zeplastiki ezenziwe kusetyenziswa le ndlela.

Yintoni iPlasstiki yokuTofa ukuBumba?

Ukubumba inaliti yeplastiki yinkqubo yokuvelisa efaka imathiriyeli yeplastiki etyhidiweyo kwindawo yokungunda phantsi koxinzelelo oluphezulu.Impahla yeplastiki idla ngokuba yi-thermoplastic, oku kuthetha ukuba inokunyibilika kwaye yomelele izihlandlo ezininzi ngaphandle kokunciphisa kakhulu iimpawu zayo zomzimba.Inkqubo iqala ngokufudumeza kunye nokunyibilika kwezinto zeplastiki, ezithi zifakwe kwi-mold cavity ngokusebenzisa inkqubo ye-injection ye-screw.Emva kokuba i-material sele ipholile kwaye yaqina ngaphakathi kwi-mold, iyakhutshwa kwaye umjikelezo omtsha uqala.

Ukuguquguquka kokuBumba kwesitofu sePlastiki

Enye yeenzuzo eziphambili zokubumba inaliti yeplastiki kukuguquguquka kwayo okungenakulinganiswa.Inkqubo inokuvelisa iimveliso zeplastiki ezinobunzima obuhlukeneyo kunye nobukhulu.Ukusuka kwizinto ezincinci, ezintsonkothileyo ukuya kwizinto ezinkulu zeemoto, ukubumba inaliti yeplastiki kunokujongana nayo yonke into.Makhe sihlolisise ezinye zeemveliso zeplastiki eziqhele ukwenziwa kusetyenziswa le ndlela yokuvelisa.

1. Izinto zokupakisha:

Ukubumba isitofu kudlala indima ebalulekileyo ekuveliseni iintlobo ngeentlobo zezinto zokupakisha ezisetyenziswa ngokubanzi kumashishini okutya, isiselo kunye nempahla yabathengi.Iibhotile zeplastiki, izivalo, izikhongozeli kunye neebhabhu yimizekelo nje embalwa.Inkqubo ivelisa ukupakishwa okukhaphukhaphu kodwa okuzinzileyo okuqinisekisa ukhuseleko lwemveliso, lula kunye nobomi obandisiweyo beshelufu.

2. Ii-Electronics zabathengi:

Ukubumba inaliti yeplastiki kusetyenziswa ngokubanzi kwimveliso yombane wabathengi.Ukusuka kwiifowuni eziphathwayo kunye neelaptops ukuya koomabonakude kunye neekhonsoli zomdlalo, ipesenti enkulu yezi zixhobo zenziwa kusetyenziswa ukubumba inaliti.Obu buchule bokuvelisa buvumela uyilo oluntsonkothileyo, ukunyamezelana okuqinileyo, kunye nokugqitywa okugudileyo okubaluleke kakhulu kubuhle kunye nokusebenza kweemveliso zombane.

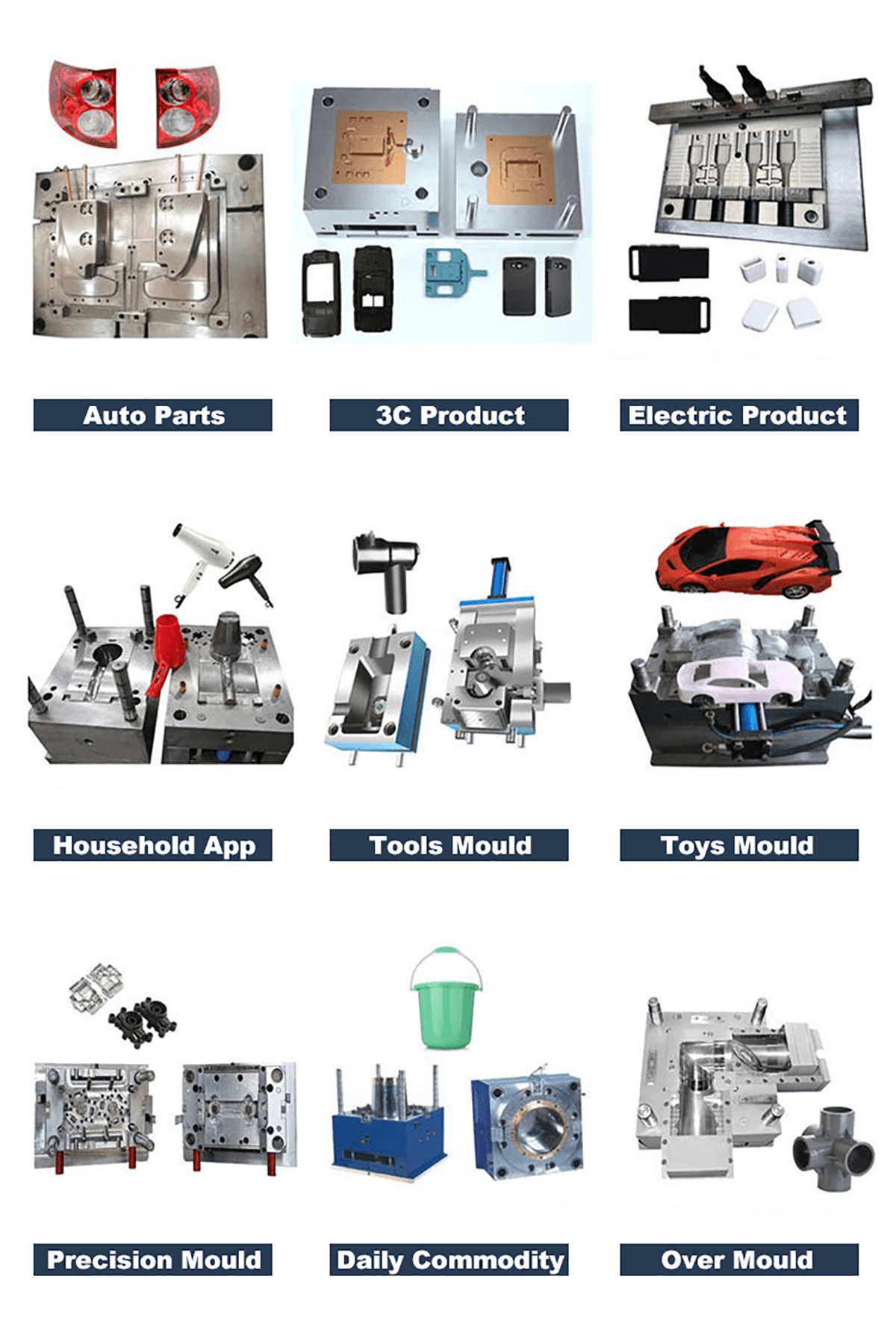

3. Amalungu e-Auto:

Umzi-mveliso weemoto uxhomekeke kakhulu ekubunjweni kwenaliti yeplastiki ukuvelisa izinto ezahlukeneyo zesithuthi.Amacandelo angaphakathi afana needeshibhodi, ii-consoles, iipaneli zeengcango kunye neendawo zokuhlala zihlala zenziwe kusetyenziswa le nkqubo.Ukongeza, amacandelo angaphandle afana ne-bumpers, i-grilles kunye ne-mirror housings i-injection-molded.Ukukwazi ukuvelisa iimilo ezintsonkothileyo, ukudibanisa imisebenzi emininzi kunye nokufezekisa uyilo olukhaphukhaphu kwenza ukuba inaliti yokubumba ilungele ishishini leemoto.

4. Izixhobo zonyango:

Ukubunjwa kwe-injection kudlala indima ebalulekileyo kwimveliso yezixhobo zonyango kunye nezixhobo.Amalungu afana neesirinji, ii-stopcocks, ii-catheters kunye neenkqubo zokuhanjiswa kweziyobisi zifuna ukuchaneka okuphezulu, ukuhambelana kwezinto eziphilayo kunye nokuqina.Ukubumba inaliti yeplastiki kuvumela ukuveliswa kobuninzi bezi zinto zintsonkothileyo nezibuthathaka zonyango ngelixa kuqinisekiswa amanyathelo angqongqo olawulo lomgangatho.

5. Izinto zokudlala kunye neemveliso zokuzonwabisa:

Isitofu sokubumba senze inguqu kwishishini lezinto zokudlala, sivumela ukuveliswa kobuninzi beentlobo ezininzi zezinto zokudlala kunye neemveliso zokuzonwabisa.Izitofu zeplastiki zokubumba zikwenza kube lula ukwenza iithoyi ezithambileyo nezinemibala.Ukongeza, izinto ezinje ngezixhobo zemidlalo, izixhobo zegadi, kunye nezixhobo zokukhempisha zixhamla ekusebenzeni kakuhle kunye nesantya esinikezwa kukubumba inaliti.

6. Izinto zasekhaya:

Uninzi lwezinto zeplastiki zasendlwini esizisebenzisa yonke imihla zenziwe ngokubumba inaliti.Izinto ezifana nezixhobo zasekhitshini, izitya zokugcina, iimpahla zokuxhoma iimpahla kunye nezixhobo ezincinci zenziwa ngale nkqubo.Ukubunjwa kwe-injection kunokuvelisa ezi mveliso ngokukhawuleza nangeendleko ezifanelekileyo, okwenza ukuba zifikeleleke kwimarike yobuninzi.

ukuququmbela:

Ukubumba inaliti yeplastiki ngokungathandabuzekiyo kuguqule ukuveliswa kweemveliso zeplastiki kuwo wonke amashishini.Ngokuguquguquka kwayo, ukusebenza kakuhle, kunye nokukwazi ukwenza iinxalenye ezintsonkothileyo ngeyona ndlela ichanekileyo, le nkqubo yokuvelisa iye yaba lukhetho lokuqala lwabenzi abaninzi kwihlabathi liphela.Ukusuka kwizinto zokupakisha ukuya kwiindawo zemoto, i-electronics ukuya kwizixhobo zonyango, iithoyi ukuya kwizinto zasekhaya - ukubunjwa kwenaliti yeplastiki kuye kwalungisa ihlabathi lethu, kudala iindidi zeemveliso zeplastiki eziluncedo eziphucula ubomi bethu bemihla ngemihla.

Iinkcukacha zeMveliso

| Indawo yeMvelaphi | eTshayina |

| Igama lebrand | HSLD/ Yenzelwe wena |

| Indlela yokuBumba | Fans Plastic Isitofu Mold |

| Izixhobo | I-CNC, i-EDM yokusika umatshini, oomatshini bePlastiki, njl |

| IMveliso yeMveliso | Intsimbi: AP20/718/738/NAK80/S136 Iplastiki: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Ubomi boMngundo | 300000 ~ 500000 Shots |

| Imbaleki | Imbaleki eshushu okanye iMbaleki ebandayo |

| Uhlobo lwesango | Umda / indawo yePin / iNqanaba / iSango elisecaleni |

| Unyango lomphezulu | Imatte, ikhazimlisiwe, iMirror ipolishiwe, ukuthungwa, ukupeyinta, njl. |

| Umngxunya womngundo | Umngxuma omnye okanye ophindaphindayo |

| Ukunyamezelana | 0.01mm -0.02mm |

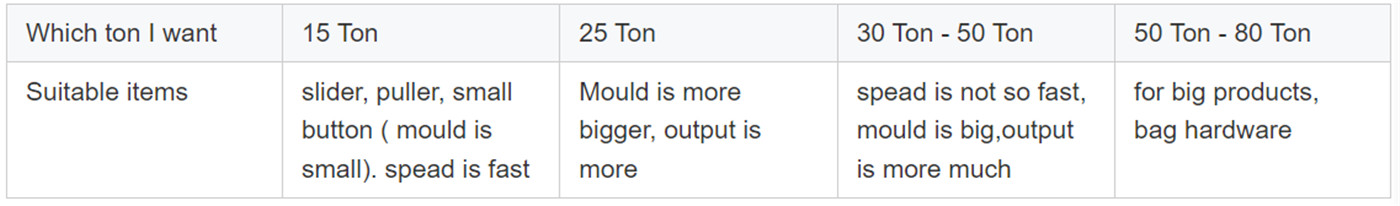

| Umatshini wokutofa | 80T-1200T |

| Ukunyamezelana | ± 0.01mm |

| Isampulu yasimahla | ekhoyo |

| Inzuzo | isisombululo esinye sokumisa / uyilo lwasimahla |

| Indawo yosetyenziso | Iimveliso ze-elektroniki, iimveliso zobuhle, iimveliso zonyango, iimveliso ezisetyenzisiweyo ekhaya, iimveliso ezizenzekelayo, njl |

Factory Iinkcukacha

More Molds

Ukuthunyelwa ngenqanawa

Inkonzo yokupakisha ekhethekileyo kuwe: Ityala leplanga elinefilimu

1. Ukuqinisekisa ngcono ukhuseleko lwempahla yakho, professional.

2. Ilungile kwimeko-bume, iinkonzo zokupakisha ezifanelekileyo nezisebenzayo ziya kubonelelwa.

FAQ

I-HSLD: Ewe, ngokuqhelekileyo iindawo ezisecaleni ze-die casting mold sinokufaka i-mold, i-mold frame, i-window core, i-core ehambayo, intloko ye-nozzle.Ungajonga kwaye uxelele ukuba zeziphi iindawo ezisecaleni ozifunayo.

I-HSLD: Isifakelo sethu sokungunda senziwe ngeDAC.

I-HSLD: Isiseko sethu esishukumayo senziwe nge-FDAC.

HSLD: Ewe.

I-HSLD: Izixhobo ezahlukeneyo zinokuchaneka okwahlukileyo, ngokubanzi phakathi kwe-0.01-0.02mm

-

Umngundo wokomisa iinwele-Ifanelekile kwi-Appli yasekhaya...

-

Isitofu sePlastiki esiphathwayo seBlender yePlastiki iNdawo...

-

IiFani ezidumileyo zoMenzi wePlastiki Amalungu eSitofu...

-

Isitofu sePlastiki seseti yonke ye-blender mol...

-

Isitofu sePlastiki sokuBumba kwiMveliso yeToy

-

Izixhobo zePlastiki zoMenzi weSixhobo esiNcinci seKhaya...