Ukubumba kwangaphambili ukwenza kunye noyilo lweemveliso zasimahla

Amacandelo ePlastiki eSitofu sokuBumba-uYilo kunye neMveliso yeeMfuno zakho

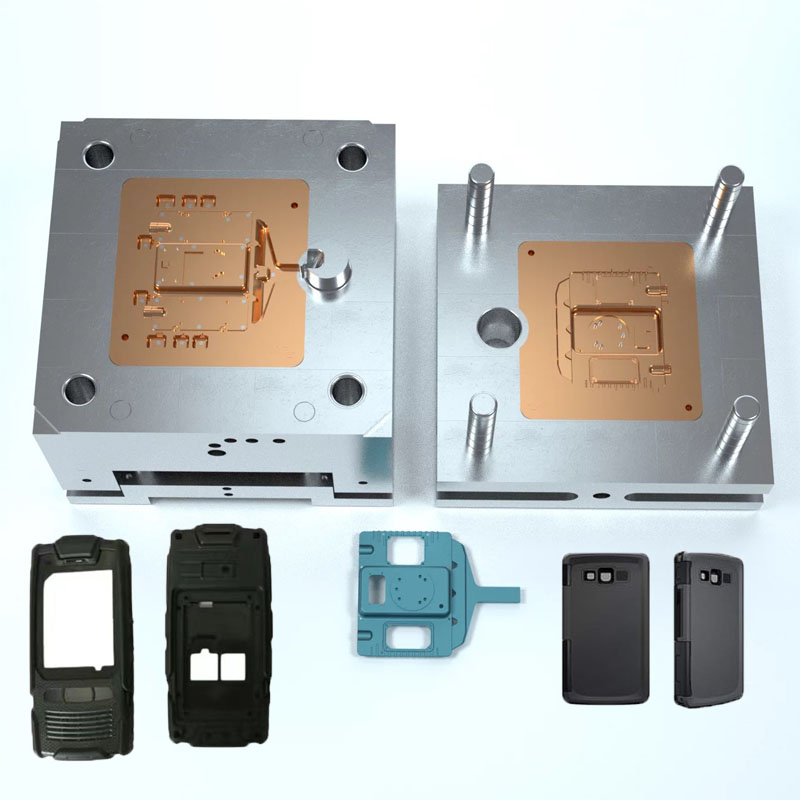

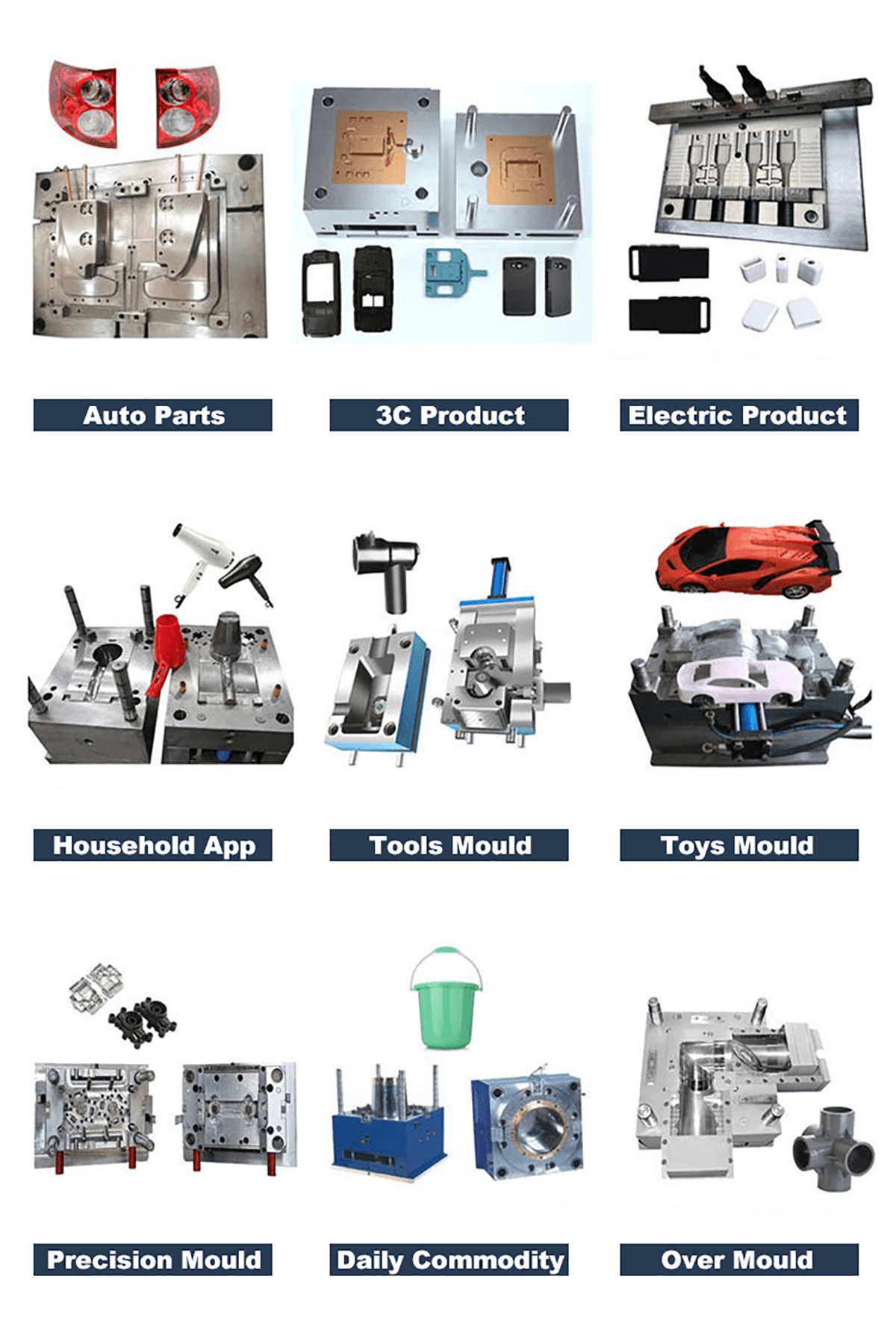

Kwinkampani yethu, siyazingca ngokubonelela ngenkonzo yodidi lokuqala kwicandelo lokwenziwa kwamalungu enziwe ngenaliti yeplastiki.Ngokuchaneka okuphezulu kokubumba okwenziweyo kunye netekhnoloji yokubumba inaliti yokusika, siyakwazi ukuvelisa iinxalenye zeplastiki ngokulula.Iqela lethu leenjineli ezinezakhono eziphezulu lizinikele ekwenziweni kwangethuba kweendawo ezibunjiweyo zeplastiki ezinomgangatho ophezulu wokusebenza.Ngamava angaphambili, senze ngempumelelo iimbumba kumashishini ahlukeneyo, kubandakanywa izixhobo zasekhaya, iithoyi, iimveliso ze-elektroniki ze-3C, iinxalenye zemoto kunye nezinto eziyimfuneko zemihla ngemihla, njl. Ukongeza, umthamo wethu wenyanga wemveliso usenza sikwazi ukuvelisa iiseti ezingama-200 zokubumba ezichanekileyo kunye nokutofa i-200,000. -500,000 iziqwenga zamalungu eplastiki.

Xa kusenziwa isitofu samalungu abunjiweyo, ukuchaneka kunye nomgangatho kubaluleke kakhulu.Ukuqonda ukubaluleka kwezi zinto, inkampani yethuutyala imali kwitekhnoloji yamva nje kunye noomatshiniukuqinisekisa ukuba sihambisa iimveliso ezihlangabezana nokulindelwe ngabathengi bethu.

Elinye lamandla ethu likubumba oluchanekileyo oluphezulu esilwenzayo.Ezi zibumba zidlala indima ebalulekileyo kwinkqubo yokubumba inaliti njengoko zimisela imilo yokugqibela kunye nomgangatho wenxalenye.Iinjineli zethu zinobuchule bokwenza umngundo, ziqinisekisa ukuba umngundo ngamnye uyilwe ngocoselelo kwaye wenzelwe ukuhlangabezana neenkcukacha zabathengi bethu.Nokuba luyilo oluntsonkothileyo okanye olulula, iqela lethu linobuchule bokwenza imibumbo evelisa iinxalenye zeplastiki ezikumgangatho ophezulu.

Ukongeza kubuchwephesha bethu bokwenza umngundo, sityale imali koomatshini banamhlanje bokubumba inaliti.Aba matshini baxhotyiswe ngeempawu eziphambili ezisivumela ukuba sivelise iinxalenye zeplastiki ngokufanelekileyo nangokuchanekileyo.Ngoncedo lwaba matshini, siyakwazi ukufumana iziphumo ezihambelanayo, ukuqinisekisa ukuba inxalenye nganye ihlangabezana nemigangatho efunekayo.Ngaphaya koko, inkqubo yethu yokubumba inaliti izenzekela kakhulu, inciphisa umngcipheko weempazamo kunye nokunciphisa amaxesha emveliso.

Inkampani yethu ibonelela ngeendidi ezininzi zamashishini, kubandakanya izixhobo zasekhaya, iithoyi, iimveliso ze-elektroniki ze-3C, iinxalenye zemoto kunye neemfuno zemihla ngemihla.Amava ethukula mashishini isinika ukuqonda okunzulu kweemfuno zabo ezithile.Olu lwazi lusenza sikwazi ukubonelela ngezisombululo zesiko ezihlangabezana neemfuno ezizodwa zabathengi bethu.Nokuba yimveliso encinci eqhutywayo okanye iprojekthi enkulu, sizibophelele ekuziseni iindawo ezibunjiweyo ezibunjiweyo zenaliti ezikumgangatho ophezulu ezingaphaya kobekulindelekile.

Xa sisebenza nabathengi, sibeka phambili unxibelelwano olucacileyo kunye nokuqonda.Ukususela ekudibaneni kokuqala ukuya kunikezelo lokugqibela, sisebenza ngokusondeleyo nabathengi bethu ukuqinisekisa ukuba iimfuno zabo ziyafezekiswa.Iqela lethu leenjineli kunye namagcisa akhona ukusombulula nayiphi na imiba okanye imibuzo enokuthi ivele.Sikholelwa ukuba unxibelelwano olusebenzayo lungundoqo kwintsebenziswano eyimpumelelo kwaye sizama ukwakha ubudlelwane obuhlala ixesha elide kunye nabaxhasi bethu.

Ngokumalunga nomthamo wemveliso, siyakwazi ukuphatha iiprojekthi ezinkulu.Ngomthamo wemveliso yeeseti ezingama-200 zokubumba ezichanekileyo ngenyanga kunye nokukwazi ukutofa i-mold 200,000-500,000 iinxalenye zeplastiki, sinokuhlangabezana nemihla yokugqibela yokuhanjiswa ngaphandle kokubeka umgangatho.Iinkqubo zethu zemveliso ezisebenzayo kunye nokuhamba komsebenzi olungelelanisiweyo kusivumela ukuba sikhulise imveliso kwaye siqinisekise ukuba abathengi bethu bafumana iiodolo zabo ngexesha.

Ukuqukumbela, inkampani yethu ngumboneleli othembekileyo wezinto ezibunjiweyo ezikumgangatho ophezulu.Ngokuchaneka okuphezulu kokubumba okwenziweyo kunye netekhnoloji yokubumba inaliti yokusika, siyakwazi ukuvelisa iinxalenye zeplastiki ngokulula.Amava ethu, ubuchule kunye nokuzibophelela kwethu kumgangatho kusenza ukuba sikhethe kuqala kumashishini afana nezixhobo zasekhaya, iithoyi, ii-elektroniki ze-3C, iinxalenye zemoto kunye neemfuno zemihla ngemihla.Ke nokuba ufuna imveliso encinci okanye iprojekthi enkulu, iqela lethu lilungele ukuhambisa iziphumo ezibalaseleyo.

Iinkcukacha zeMveliso

| Indawo yeMvelaphi | eTshayina |

| Igama lebrand | HSLD/ Yenzelwe wena |

| Indlela yokuBumba | Fans Plastic Isitofu Mold |

| Izixhobo | I-CNC, i-EDM yokusika umatshini, oomatshini bePlastiki, njl |

| IMveliso yeMveliso | Intsimbi: AP20/718/738/NAK80/S136 Iplastiki: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Ubomi boMngundo | 300000 ~ 500000 Shots |

| Imbaleki | Imbaleki eshushu okanye iMbaleki ebandayo |

| Uhlobo lwesango | Umda / indawo yePin / iNqanaba / iSango elisecaleni |

| Unyango lomphezulu | Imatte, ikhazimlisiwe, iMirror ipolishiwe, ukuthungwa, ukupeyinta, njl. |

| Umngxunya womngundo | Umngxuma omnye okanye ophindaphindayo |

| Ukunyamezelana | 0.01mm -0.02mm |

| Umatshini wokutofa | 80T-1200T |

| Ukunyamezelana | ± 0.01mm |

| Isampulu yasimahla | ekhoyo |

| Inzuzo | isisombululo esinye sokumisa / uyilo lwasimahla |

| Indawo yosetyenziso | Iimveliso ze-elektroniki, iimveliso zobuhle, iimveliso zonyango, iimveliso ezisetyenzisiweyo ekhaya, iimveliso ezizenzekelayo, njl |

Ukubunjwa kwesitofu sePlastiki: Umtshintshi weMidlalo kuMacandelo e-B-End

Intshayelelo

Ukubumba inaliti yePlasitiki kuziguqule ngokwenene iinkqubo zokwenziwa kwemveliso kuwo wonke amashishini e-B-End, okuvula amathuba angenasiphelo okwenziwa kwezinto ezintsha kunye nenkqubela phambili.Kweli nqaku liphakamisayo, siza kuphonononga kwihlabathi elikhulu nelinomdla lokubumba inaliti yeplastiki kwimveliso yeemoto, i-elektroniki yabathengi, ishishini lokupakisha, kunye nokhathalelo lwempilo.Ngokubonisa imizekelo yokwenyani kwaye siyixhasa ngedatha ekhuthazayo, siya kupeyinta umfanekiso ocacileyo wendlela obu buchule busebenza ngeendlela ezininzi butshintshe kwaye baphucule ngokuphawulekayo la macandelo.

Ukubunjwa kwesitofu sePlastiki kwiMveliso yeeMoto

Ishishini leemoto linegama lokuqamba izinto ezintsha kunye nokuphuculwa rhoqo.Ukususela kwiinjini zanamhlanje ukuya kwiimpawu ezikhuselekileyo zokhuseleko, abavelisi bahlala befuna iindlela zokuphucula ukusebenza kwesithuthi kunye nobuhle.Indlela yohlaziyo etshintsha umdlalo wokwenziwa kweemoto kukubumba inaliti yeplastiki.

Ukusebenzisa le nkqubo yokuphumelela, abavelisi babone ukugcinwa kwexesha elibalulekileyo lokuvelisa i-25% kunye nokunciphisa inkunkuma yezinto eziphathekayo nge-30% xa kuthelekiswa neendlela zendabuko, ngokutsho kwe-Society of Automotive Technology report.Ezi nkcukacha-manani zinyanzelisayo zigxininisa ubume bokuphazamiseka kokubumba inaliti yeplastiki.Ayiphelelanga nje ekuguquleni ukwenziwa kwezinto ezintsonkothileyo ezikhaphukhaphu ezifana needashbhodi, iibhampa kunye neegrilles, kodwa ikwazile ukuba abaqulunqi beemoto baphumeze iimilo ezikumgangatho ophezulu kunye neenkcukacha ezinokunceda ukuphucula ukusebenza kakuhle kwamafutha.

Ukubumba inaliti yeplastiki bubuchule bokuvelisa obufaka iplastiki etyhidiweyo kumgodi wokungunda.Yakuba ipholile yaza yoqina, inxalenye yeplastiki iyakhutshelwa kumngundo ukuze yenze imveliso yokugqibela echanekileyo neyomelelayo.Inkqubo ineenzuzo ezininzi kwiindlela zokuvelisa zemveli.

Okokuqala nokuphambili, ukubumba inaliti yeplastiki kwenza kube lula ukuvelisa iindawo ezinzima.Ukusebenzisa isoftware yoyilo oluncediswa yikhompyuter (CAD), abaqulunqi beemoto banokwenza iimodeli ze-3D zamacandelo afunwayo.Le mizekelo iguqulwa ibe yimbumba, iqinisekisa ukuba yonke inxalenye eveliswayo isoloko ichanekile kwaye ihambelana.

Ukongeza, ukusetyenziswa kweukubumba inaliti yeplastiki yemotoyenza amacandelo alula ngaphandle kokubeka esichengeni amandla kunye nokuqina.Oku kuphucula ukusebenza kakuhle kwamafutha, ekubeni izithuthi ezikhaphukhaphu zifuna amandla amancinci ukuze zihambe.Ukongeza, ubume obukhaphukhaphu bala macandelo abunjiweyo bunegalelo ekusebenzeni kwesithuthi ngokubanzi, kubandakanya ukuphathwa okuphuculweyo kunye nemigama emifutshane yokumisa.

Enye inzuzo ebalulekileyo yokubumba inaliti yeplastiki kwimveliso yeemoto kukukwazi kwayo ukunciphisa inkunkuma yezinto.Ngokungafaniyo neendlela zemveli, ezihlala zibandakanya ukusika ngokugqithisileyo kunye nokubunjwa kwezinto, ukubumba inaliti yeplastiki kuqinisekisa ukuba inkunkuma iyancitshiswa.Ukongeza, ukukwazi ukuphinda kusetyenziswe iplastiki eshiyekileyo kubumba obudlulileyo kugxininisa ngakumbi ukuzinzileyo kwenkqubo.

Ngokwamkela ukubumba inaliti yeplastiki, ii-automakers zifikelela kubude obutsha bokuyila, ukusebenza kakuhle kunye nokuzinza.Le ndlela yokuvelisa intsha ayitshintshanga nje kuphela indlela amacandelo eemoto eveliswa ngayo, kodwa inike abayili inkululeko yokuphonononga iimilo zenoveli kunye neenkcukacha.Isiphumo sibonakala izithuthi ezikhangayo ezibhenela kubathengi ngelixa zinegalelo kwikamva eliluhlaza.

Ukuqukumbela, ukubumba inaliti yeplastiki kuguqule ishishini leemoto.Ubuchule bayo bokudala iindawo ezinzima, ezikhaphukhaphu ezinemilo ekhethekileyo kunye neenkcukacha ziqhubele phambili ishishini.Le ndlela ayigcini nje ngokubangela ukonga iindleko ezibalulekileyo kunye nokunciphisa inkunkuma yezinto eziphathekayo, kodwa inceda ekuphuculeni ukusebenza kakuhle kwamafutha kunye nokusebenza kwesithuthi ngokubanzi.Ngokubumba inaliti yeplastiki, abavelisi beemoto banokuqhubeka nokutyhala imida yokuyila iimoto ezingafezekisiyo iimfuno zabathengi kuphela kodwa zinegalelo kwikamva elizinzileyo.

Isitofu sokubumba kwi-Electronics yabaThengi: Ukutshintsha iShishini

Ii-elektroniki zabathengi ziye zaba yinxalenye ebalulekileyo yobomi bethu, kunye nee-smartphones, iilaptops kunye nezixhobo zasekhaya ezidlala indima ebalulekileyo ekuphuculeni ubomi bethu bemihla ngemihla.Emva kwemiboniso, inkqubo ephawulekayo yokuvelisa ebizwa ngokuba yi-plastic injection molding idlale indima enkulu ekutshintsheni indawo ye-electronics yabathengi, ivumela ukuveliswa kwezinto ezinzima kunye nokuqhuba ukutsha kolu shishino lukhulayo.

Ukubumba inaliti yePlastiki kuyiguqule inkqubo yokuvelisa izinto zombane zabathengi, nto leyo evumela abavelisi ukuba benze uyilo oluntsonkothileyo noluchanekileyo olwalungenakufikelelwa ngaphambili.Enye indawo apho ukubumba inaliti yeplastiki kuye kwaba nempembelelo enkulu kukubumba iiplastiki zombane.Inkqubo ibandakanya ukutofa iplastiki enyibilikisiweyo kwimibumbo eqhelekileyo ukwenza iinxalenye zeplastiki ezingenamthungo nezomeleleyo zezixhobo zombane.

Ngombulelo kule nkqubo yokubona kude, abavelisi baye bazuza ukonga okubalulekileyo ukuya kuthi ga kwi-35% kwiindleko zemveliso (umthombo: i-Electronic Manufacturers Association).Ngokwenza lula inkqubo yokuvelisa kunye nokuphelisa imfuno yamacandelo amaninzi kunye neendibano, ukubumba inaliti yeplastiki akunciphisi ixesha lokuvelisa kuphela, kodwa kwandisa ukusebenza kakuhle kwenkqubo yokuvelisa.Ngenxa yoko, iinkampani kwishishini le-elektroniki labathengi bafumana imveliso ekhawulezayo yemveliso kunye nenzuzo ephuculweyo.

Inkampani yethu iOEM / ODMumthengisi womvelisi osebenza ngokubumba inaliti yeplastiki kubathengi be-elektroniki.Ngokungunda kwethu kuthunyelwa kumazwe angaphezu kwama-20, siye safumana amava abanzi ekufezekiseni iimfuno ezizodwa zeemarike ezahlukeneyo.Siyazingca ngoyilo lwethu lokubumba kunye nobuchule bokwenza, siqinisekisa ukuba abathengi bethu bafumana ukubumba okukumgangatho ophezulu kunye nokuthembekileyo.

Kwi-electronics yabathengi, ubuhle kunye noyilo ludlala indima ebalulekileyo.Iplastiki yimathiriyeli ethambileyo kakhulu enokuthi idibanise ngaphandle komthungo imisebenzi yobuchule obutsha kunye noyilo lomntu ngamnye.Ukukwazi ukuzama izixhobo ezahlukeneyo ezifana ne-polycarbonate (i-PC) ivula indlela ye-electronics eyomeleleyo nebukekayo.Ukubumba inaliti yePC luhlobo olusezantsi lwesitofu seplastiki esinokuvelisa iinxalenye ezineempawu ezibalaseleyo zoomatshini, ukumelana nobushushu obuphezulu kunye nokucaca okugqwesileyo kwamehlo.Oku kuye kwaphakamisa ngokufanelekileyo ibha kwi-electronics yabathengi, ukubonelela abasebenzisi ngezixhobo ezingenzi kakuhle kuphela, kodwa ziphucukile kwaye ziphucukile kuyilo.

Ukubumba inaliti yeplastikiuye watyhalela abathengi kwi-electronics kummandla wamathuba angapheliyo.Ukungenamthungo kunye nokusebenza kakuhle kwale nkqubo yokuvelisa ivumela abavelisi ukuba bahlangabezane neemfuno ezihlala zitshintsha zabathengi be-tech-savvy.Ukusuka kwii-smartphones ezine-bezel-less displays ukuya kwiilaptops ezine-ultra-thin form factor, ukubunjwa kwenaliti yeplastiki bekuphambili ekudaleni izixhobo ezingezizo ezobuchwephesha kuphela kodwa zibukeka zintle.

Ukuqukumbela, ukubumba inaliti yeplastiki kuguqule ishishini lombane labathengi.Ngokukwazi ukuvelisa izixhobo ezintsonkothileyo ngokukhawuleza nangeendleko eziphantsi, abavelisi baye bamkela le nkqubo ukuzisa izixhobo ezibukhali kwintengiso.Ngokudibanisa uyilo oluyintshayo kunye nemathiriyeli eyomeleleyo efana nepolycarbonate, ukubumba inaliti yeplastiki kukwazile ukwenza umdla kunye nonomtsalane wombane wabathengi.Enkosi kule nkqubo yokwenziwa esebenzayo, ikamva labathengi be-elektroniki libonakala liqaqambile kunangaphambili, kunye noluhlu lwezixhobo ezivelisa izinto ezintsha nezibukekayo ekulindeleke ukuba zonwabise abantu abathanda itekhnoloji kwihlabathi jikelele.

Ukubunjwa kwesitofu sePlastiki kwiShishini lokuPakisha

Umzi-mveliso wokupakisha, owaziwa ngokuyila kunye nokusungula izinto ezintsha, ufumene uhlaziyo ngokufika kokubumba inaliti yeplastiki.Ngokwamkela le teknoloji yempumelelo, abavelisi banokunciphisa kakhulu iindleko zabo zemveliso nge-40% (umthombo: Umbutho weeNgcweti zokuPakisha).

Ukubumba inaliti yeplastiki kuye kwayiguqula indlela izisombululo zokupakishwa ezenziwe ngayo, ngakumbi ngokubumba kwangaphambili, i-PET preform molds, i-caps yeplastiki yokubumba kunye nokubumba kwangaphambili.Ezi zibumba zibalulekile kwimveliso yezinto ezahlukeneyo zokupakisha kubandakanya iibhotile, izikhongozeli kunye nokuvalwa.

Ukuguquguquka kokubumba inaliti yeplastiki kunokuvelisa izisombululo zokupakisha ezikhangayo ezingaqinisekisi kuphela ukhuseleko lwemveliso kunye nokuphila ixesha elide, kodwa zikwatsala abathengi ngezinto zokuyila zamehlo.Ngokusebenzisa i-molds ye-preform, abavelisi bayakwazi ukwenza iibhotile kunye nezikhongozeli ezingenamthungo nezinomtsalane.I-PET preform molds ngokukodwa ivelisa izisombululo zokupakisha ezicacileyo kunye nezomeleleyo ezisetyenziswa ngokubanzi kwimizi-mveliso yesiselo kunye nokutya.

Ukongeza, i-caps yeplastiki yokubumba inokubangela ukuvalwa okukhuselekileyo kunye nobungqina bokuvuza kwiibhotile kunye nezikhongozeli.Ezi zivalo azikhuseli kuphela iziqulatho zepakethe, kodwa zibonelela ngokulula kunye nokulula ukusetyenziswa kwabathengi.Ukuchaneka kunye nokusebenza kakuhle kokubumba inaliti yeplastiki kuqinisekisa ukuba yonke i-cap eveliswayo isemgangathweni ongaguqukiyo, okukhokelela kwisisombululo esithembekileyo sokupakisha.

Ngaphaya koko, ukubumba i-preform blowing kuye kwaba yindlela edumileyo kwishishini lokupakisha.Le nkqubo ibandakanya ukutofa imathiriyeli yeplastiki eshushu kumngundo, ethi ke yandiswe ngomoya ocinezelweyo ukuze yenze indawo yokupakisha engenanto.Ukubumba ukuvuthela kwangaphambili kunika ukuguquguquka okukhethekileyo koyilo, okwenza abavelisi benze iimilo ezizodwa kunye nobukhulu bezisombululo zabo zokupakisha.Oku akugcini nje ukuphucula i-aesthetics yemveliso, kodwa kuphucula amava omthengi.Ikhaphukhaphu kodwa yomelele, ezi zisombululo zokupakisha ezibunjiweyo zibonelela ngokulula kunye nokuphatheka kubathengi ngelixa zinciphisa iindleko zokuthumela ngenqanawa kubavelisi.

Ukubumba inaliti yeplastiki kuvula indlela yezisombululo zokupakisha ezizinzileyo kusetyenziswa imathiriyeli esetyenzisiweyo.Ishishini liya liguqukela ngakumbi kwizinto ezihambelana nokusingqongileyo ezifana ne-bioplastics, ephuma kwimithombo evuselelekayo kwaye inokuhlaziywa ngokulula.Ngokwamkela ukubumba inaliti yeplastiki, abavelisi banako ukunciphisa ifuthe labo lokusingqongileyo ngelixa bebonelela ngezisombululo zokupakisha ezintsha.

Iinkampani kwishishini lokupakisha ziye zaqaphela izibonelelo ezinkulu zokubumba inaliti yeplastiki kwaye zayibandakanya kwiinkqubo zabo zokuvelisa.Ezi nkampani zisebenzisa i-preform moulds, i-PET preform moulds, iiplastiki ze-cap molds, kunye ne-preform blow blowing itekhnoloji ukuvelisa izisombululo zokupakisha ezikumgangatho ophezulu, ezingabizi kakhulu kunye nezizinzileyo.

Lilonke, ukubumba inaliti yeplastiki kuzise utshintsho olukhulu kwishishini lokupakisha.Ngokusebenzisa iimolds ze-preform, ii-PET preform moulds, i-plastiki cap moulds, kunye ne-preform blow blowing technologies, abavelisi baye bakwazi ukuvelisa izisombululo zokupakisha eziqinisekisa ukhuseleko lwemveliso, ixesha elide kunye nokwaneliseka kwabathengi.Ngaphaya koko, ukubumba inaliti yeplastiki kunceda uphuhliso lwezisombululo zokupakisha ezizinzileyo, ezinegalelo ekucuthweni kwempembelelo yokusingqongileyo yeshishini.Ngokuguquguquka kwayo kunye nokusebenza kakuhle kweendleko, ukubumba inaliti yeplastiki kuhlala kuseyona nto iqhuba ukubumba ikamva leshishini lokupakisha.

I-Plassic Injection Molding in Healthcare: Ukuguqula uKhuseleko lweSigulane kunye neMpilontle kukhathalelo lwempilo

Iinkqubo zokuvelisa ezichanekileyo nezithembekileyo zibalulekile ekuqinisekiseni ukhuseleko lwesigulane kunye nokuphila kakuhle.Yonke imveliso yezonyango esetyenziswa ngababoneleli bezempilo kufuneka ihlangabezane nemigangatho engqongqo yomgangatho, ukuchaneka kunye nobunyumba.Ukufezekisa ezi njongo, ukuqaliswa kokubumba inaliti yeplastiki ngokungathandabuzekiyo yayilutshintsho.Le nkqubo yokuvelisa iguqule imboni yezempilo ngokuvumela abavelisi ukuba banikezele ngeemveliso zonyango ezichanekileyo, ezikumgangatho ophezulu.Ababoneleli ngezempilo babone ukuphucuka okumangalisayo kokuchaneka kwemveliso ngenxa yokubumba inaliti yeplastiki.Ngokutsho koMbutho wokuVelisa iMedical, le nkqubo ibangele ukuncitshiswa okubalulekileyo kwe-50% kwiziphene zemveliso (umthombo: i-Medical Manufacturing Association) .

Esi siqinisekiso siphezulu somgangatho sibalulekile xa kusenziwa izixhobo zonyango ezibalulekileyo njengesirinji, iikhethetha kunye nezixhobo zotyando.Ngokunciphisa iziphene, izigulane kunye nabasebenzi bezempilo banokuthembela kwezi mveliso ngokuzithemba besazi ukuba ukusebenza kwabo kunye nokhuseleko zizinto eziphambili eziphambili.Enye yeenzuzo eziphambili zokubumba inaliti yeplastiki kukukwazi ukuqinisekisa ubunyumba beemveliso zonyango.Kwimeko yokhathalelo lwempilo, umngcipheko wosulelo yeyona nto ixhalabisayo.Nangona kunjalo, ngokubumba inaliti yeplastiki, abavelisi banokuvelisa izixhobo zonyango eziyinyumba ngokuthe ngqo kwi-mold.Oku kuphelisa imfuno yeenkqubo ezongezelelweyo zokuvala inzala, ukunciphisa amandla okungcola kunye nokuphucula ukunakekelwa kwesigulane.Ngokunciphisa umngcipheko wokusuleleka, izibonelelo zempilo zinokubonelela ngendawo ekhuselekileyo yezigulane, ekugqibeleni zikhuthaze ukubuyiswa kwazo kunye nokuphila kakuhle.

Ukongeza, ukubumba inaliti yeplastiki kuvumela ukuveliswa okuchanekileyo kunye nokusebenzayo kwezixhobo zonyango ezinzima.Ukuguquguquka kwale nkqubo yokuvelisa kwenza ukuba kuyilwe uyilo oluntsonkothileyo, ukuqinisekisa ukuba iimveliso zonyango zihlangana ngokungenamthungo kwaye zenza ngokungenasiphako.Nokuba zizixhobo zotyando ezintsonkothileyo okanye iisirinji ezilungelelanisiweyo ngokuchanekileyo, ukubumba inaliti yeplastiki kuvumela abavelisi ukuba bahlangabezane neemfuno ezibangwayo zeshishini lezempilo.

Oku kuchanekileyo kunye nokusebenza kakuhle akuncedi kuphela izigulane, kukwanceda ukugcina iindleko zababoneleli bezempilo kwaye kwenza ukuba ukhathalelo olusemgangathweni lufikeleleke kuluntu olubanzi.Impembelelo yokubumba inaliti yeplastiki kukhathalelo lwempilo idlulela ngaphaya kwenkqubo yokuvelisa ngokwayo.Ngokusebenzisa obu buchwepheshe buphucukileyo, ishishini lezempilo lehlabathi liphakamisa umgangatho wokugqwesa.Njengoko ukuchaneka kunye nokuthembeka kuba yinto eqhelekileyo, umgangatho jikelele weemveliso zonyango uphucula, okukhokelela kwiziphumo ezingcono zesigulane.Ukusuka ekunciphiseni umngcipheko wosulelo ukuya ekunciphiseni iziphene zemveliso, ukubumba inaliti yeplastiki kudlala indima ebalulekileyo ekusindiseni ubomi kunye nokuphucula umgangatho jikelele wokhathalelo lwesigulane.Njengoko ishishini lokhathalelo lwempilo liqhubeka nokuvela, kunjalo nesidingo seemveliso zonyango ezichanekileyo nezithembekileyo.Ukubumba inaliti yeplastiki kujongana ngqo nezi mfuno, kunika abavelisi izixhobo abazidingayo ukuhambisa umgangatho okhethekileyo kunye nobunyumba.Amandla okuguqula le nkqubo yokuvelisa ivumela ababoneleli bezempilo ukuba bagxininise kwizinto ezibaluleke kakhulu: impilo kunye nokuphila kakuhle kwezigulane zabo.

Ukuqukumbela, ukubumba inaliti yeplastiki kuye kwatshintsha umdlalo kwimveliso yezempilo.Ivumela ukuveliswa kweemveliso zonyango ezikumgangatho ophezulu, ezichanekileyo kunye neentsholongwane, ukunciphisa umngcipheko wosulelo kunye nokuphucula ukhathalelo lwesigulane.Ngale nkqubo yotshintsho, ishishini lezempilo kwihlabathi liphela lisindisa ubomi kwaye liphakamisa umgangatho wokugqwesa.Ngesidingo esikhulayo seziphumo ezingcono zesigulana, ukubumba inaliti yeplastiki ngokungathandabuzekiyo kuya kudlala indima enkulu ekubumbeni ikamva lemveliso yezempilo.

Ukuqukumbela

Ukubumba inaliti yeplastiki kuzise kwixesha lamathuba angenamda kunye notshintsho olutsha kuwo wonke amashishini e-B-End.Ngokubonisa imizekelo yelizwe lokwenyani kwaye siyixhase ngedatha enyanzelisayo, siye sabona ifuthe elimangalisayo lobu buchule kwimveliso yeemoto, i-elektroniki yabathengi, ishishini lokupakisha, kunye nokhathalelo lwempilo.Ukongiwa kweendleko, uyilo olwandisiweyo, kunye nokuchaneka kwemveliso okuphuculweyo okubonelelwa ngokubumba inaliti yeplastiki kuye kwawaguqula la macandelo, kushiya uphawu olungacimekiyo kwinkqubela phambili nokukhula kwawo.Njengoko sisamkela amathuba angenamda wokubumba inaliti yeplastiki, sibona ikamva eliqaqambileyo elizaliswe ngamandla angenasiphelo okuvelisa ukugqwesa kunye nokwaneliseka kwabathengi.

Ke, masiqalise kolu hambo lumangalisayo, apho ukuyila, ukusebenza kakuhle, kunye nozinzo zingqubana ngendlela enamandla yokubumba inaliti yeplastiki.Sikunye, sinokubumba ihlabathi apho ukutsha kungazi mda, kwaye lonke ishishini liyaphumelela ngoncedo lobu buchwepheshe bumangalisayo.

Zive ukhululekile ukubauqhagamshelwanothinananini na !Silapha ukunceda kwaye singathanda ukuva kuwe.

Factory Iinkcukacha

More Molds

Ukuthunyelwa ngenqanawa

Inkonzo yokupakisha ekhethekileyo kuwe: Ityala leplanga elinefilimu

1. Ukuqinisekisa ngcono ukhuseleko lwempahla yakho, professional.

2. Ilungile kwimeko-bume, iinkonzo zokupakisha ezifanelekileyo nezisebenzayo ziya kubonelelwa.

FAQ

I-HSLD: Ewe, ngokuqhelekileyo iindawo ezisecaleni ze-die casting mold sinokufaka i-mold, i-mold frame, i-window core, i-core ehambayo, intloko ye-nozzle.Ungajonga kwaye uxelele ukuba zeziphi iindawo ezisecaleni ozifunayo.

I-HSLD: Isifakelo sethu sokungunda senziwe ngeDAC.

I-HSLD: Isiseko sethu esishukumayo senziwe nge-FDAC.

HSLD: Ewe.

I-HSLD: Izixhobo ezahlukeneyo zinokuchaneka okwahlukileyo, ngokubanzi phakathi kwe-0.01-0.02mm